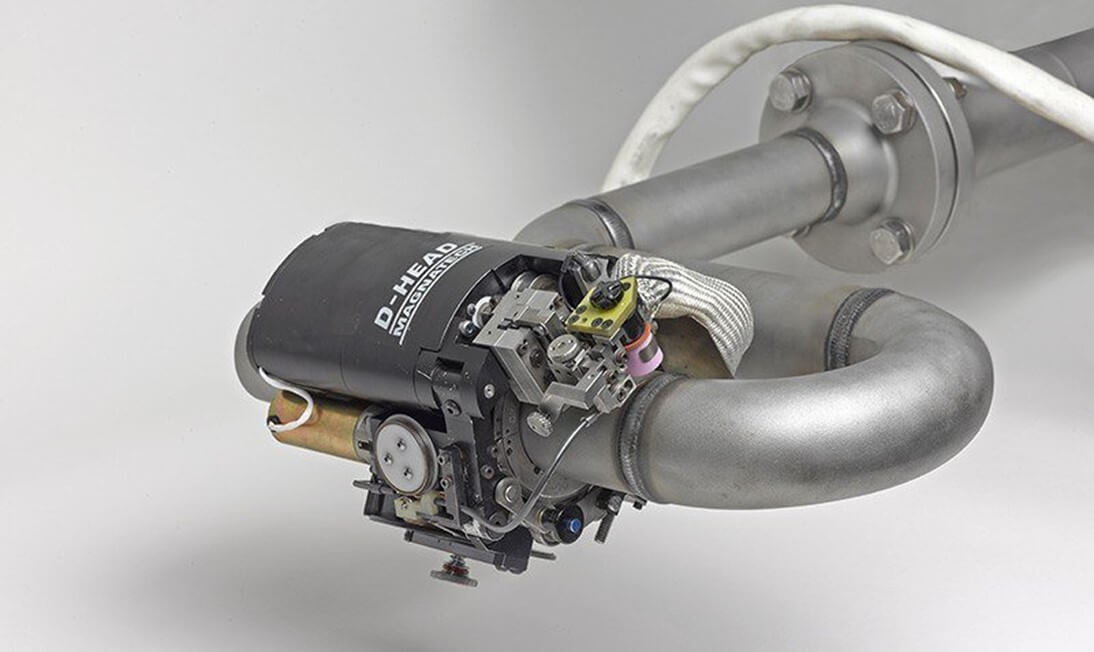

KEPUNI Revolutionizes Welding in the Food and Chemical Industries

KEPUNI has unveiled a cutting-edge closed orbital welding machine, purpose-built to meet the rigorous demands of the food and chemical industries. This innovative solution is specifically designed for stainless steel pipe applications, ensuring top-notch weld quality while addressing the critical needs of hygiene and efficiency.

The KEPUNI closed orbital welding machine leverages advanced technology to deliver unparalleled precision. Its design minimizes the risk of contamination, a paramount concern in industries where cleanliness is essential. The closed welding environment ensures consistent results, enhancing the structural integrity of stainless steel pipes that are vital for transporting food and chemicals safely.

By streamlining the welding process, KEPUNI’s new machine significantly boosts operational efficiency. Its advanced features not only reduce manual intervention but also enhance safety for operators. This combination of efficiency and safety is crucial for food and chemical processing operations, where downtime and errors can have far-reaching consequences.

Stainless steel pipes play a pivotal role in maintaining hygiene and structural reliability in both industries. KEPUNI’s equipment aligns with stringent industry regulations, enabling manufacturers to meet compliance requirements effortlessly. The machine’s state-of-the-art technology underscores KEPUNI’s commitment to delivering solutions tailored to the unique challenges of its customers.

This latest innovation by KEPUNI reflects a broader trend of advancements in welding technology. By addressing the specific needs of the food and chemical sectors, KEPUNI reaffirms its position as a leader in the industry. The closed orbital welding machine not only supports manufacturers in achieving superior weld quality but also sets a new benchmark for safety and efficiency.

With the introduction of this groundbreaking technology, KEPUNI empowers manufacturers to elevate their production standards. The ability to produce high-quality, hygienic welds efficiently is a game-changer for industries where precision and reliability are non-negotiable.

KEPUNI’s closed orbital welding machine is more than just equipment—it is a testament to the company’s dedication to innovation and excellence in the food and chemical industries.